|

|

|

304 Stainless Steel Dry And Wet

Horizontal Mixer |

|

|

|

|

|

|

|

|

The mixer adopts stainless steel blade transmission

with low noise, smooth transmission, simple

structure, convenient

installation

and maintenance, and good mixing effect.

Compared with other mixers, the horizontal mixer

has the advantages of short mixing time, wide

adaptability, no damage to

the

mixing material, easy cleaning, etc., the material will not press feed

and grind, and the mixing of coarse and fine materials also has

good adaptability. Horizontal spiral

mixer produces transverse cross

convection, mixing, diffusion and other complex movements

in the

body without destroying the mixture, so that the material can

achieve the best mixing effect in a short

time.

The mixer can process both

wet and dry materials and is capable of stirring feed particles, feed

powder, plastic pellets, fertilizers, sauces, and so on.

|

|

|

Main Parameter

Voltage:220V

Power:3KW

Capacity:200KG

The internal dimensions:

41.3″ * 23.6″ *26.7″(105*60*68cm)

|

|

|

Detail |

|

|

S-type stirring blade, stirring without

dead Angle, uniform mixing speed, easy

to

clean. |

The elongated and widened mixing tank

has a large capacity. |

|

|

High quality motor, side heat dissipation

hole, stable operation, long service life. |

Butterfly valve outlet, turn the

handle, easy to switch, good sealing,

easy to use. |

|

|

A dust-proof cover with snap fasteners.

It

can be locked in place when in use,

and is

convenient for installation and

removal. |

High quality switch, easy operation,

long service life. |

|

|

If the butterfly valve outlet fails to

empty

the internal materials, the outlet in the

middle of the barrel can also be used for

discharge. |

Six oversized supporting feet stabilize

the mixer better, and it can also be

fixed

to the ground through positioning

holes. |

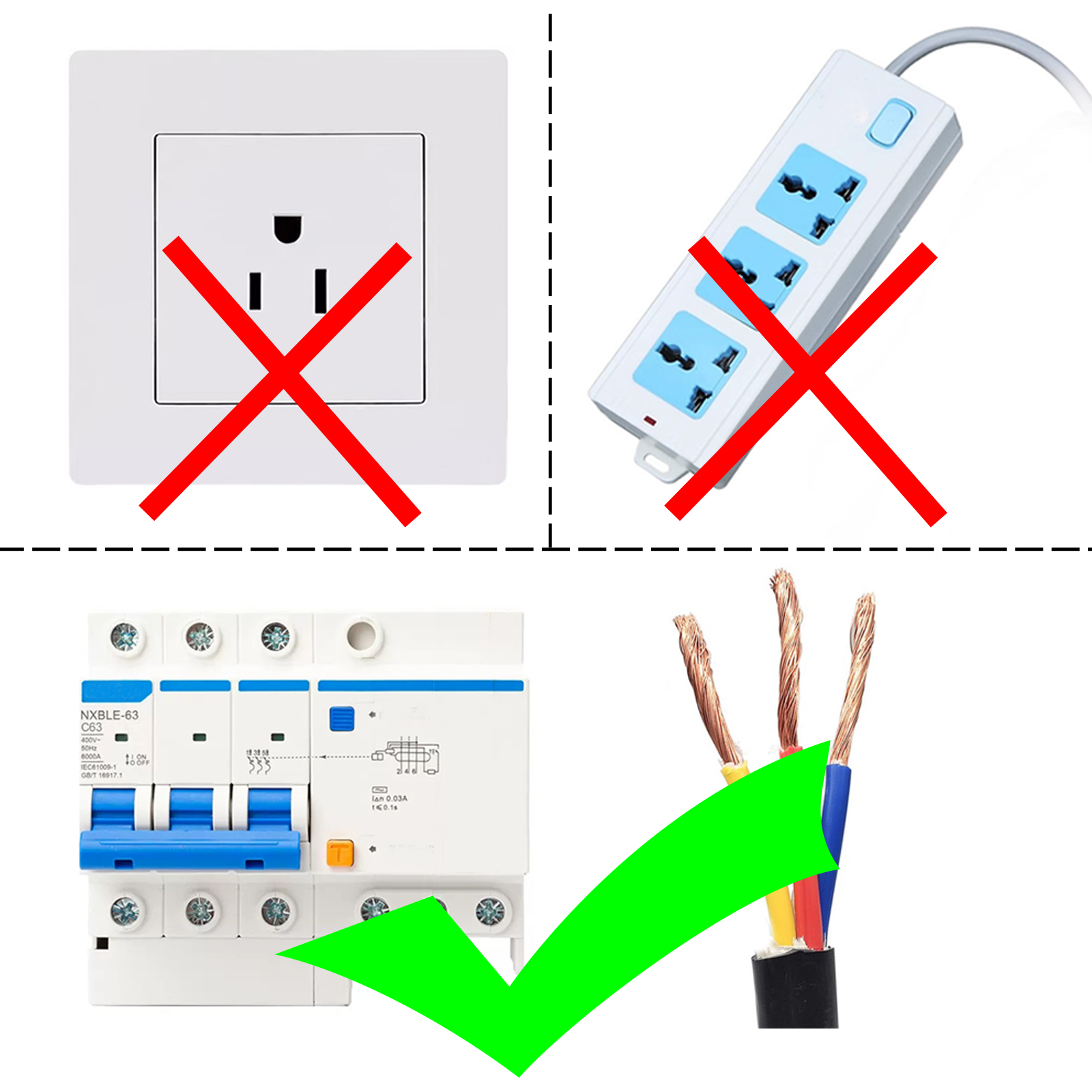

The machine does not come with a plug, please connect the

power cord to the air switch before use. |

|

|

Operation and Maintenance Guide |

1.Pre-Startup Preparation

Inspect all parts of the equipment to ensure that the mixing blades,

bearings, and seals are secure and undamaged.

Remove any foreign objects from the mixing barrel to prevent impurities

from contaminating the materials and affecting quality.

Verify that the power supply and wiring are normal, and ensure the

switches can be triggered properly.

2.Material Loading and Operation

Load materials according to the specified amount to avoid overloading,

which could cause motor overload or uneven mixing.

When starting the equipment, operate at low speed for 1–2 minutes first.

If no abnormalities are observed, proceed to load the materials.

During operation, monitor the mixing status of the materials in real

time. If unusual noises, vibrations, or material leakage occur, stop the

machine immediately for inspection.

3.Shutdown and Cleaning

After mixing is complete, shut down the equipment before opening the

discharge outlet to ensure all materials are fully discharged.

Cut off the power supply and use specialized tools to clean residual

materials from the inner wall of the mixing barrel and the mixing blades

to prevent material buildup from affecting future use.

After cleaning, inspect the equipment components and lubricate

wear-prone parts such as bearings. Regularly add lubricant to the gear

reducer.

4.Key Precautions

a. Do not insert hands or tools into the barrel while the equipment is

operating to prevent mechanical injuries.

Non-operators are not allowed to operate the equipment arbitrarily.

Before starting up, ensure there are no unauthorized personnel nearby.

b. In case of sudden malfunction, cut off the power supply before

troubleshooting. Do not perform repairs while the equipment is

energized.

c. Perform quarterly maintenance on components such as bearings and gear

reducers, supplementing or replacing lubricant to prevent damage due to

dryness.

d. If the equipment will not be used for an extended period, clean it

thoroughly, cover it with a dust-proof cover, and avoid exposure to dust

and moisture to prevent component corrosion.

e. Do not mix materials beyond the equipment’s design specifications,

such as high-viscosity or high-hardness materials, to prevent equipment

jamming or damage.

For corrosive materials, use a specialized corrosion-resistant model of

the horizontal mixer. Ordinary models will experience accelerated

component degradation if exposed to corrosive materials. |

|

|

|

Item Number: 304 Stainless Steel Dry And

Wet Horizontal Mixer 021310 |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|