|

|

|

|

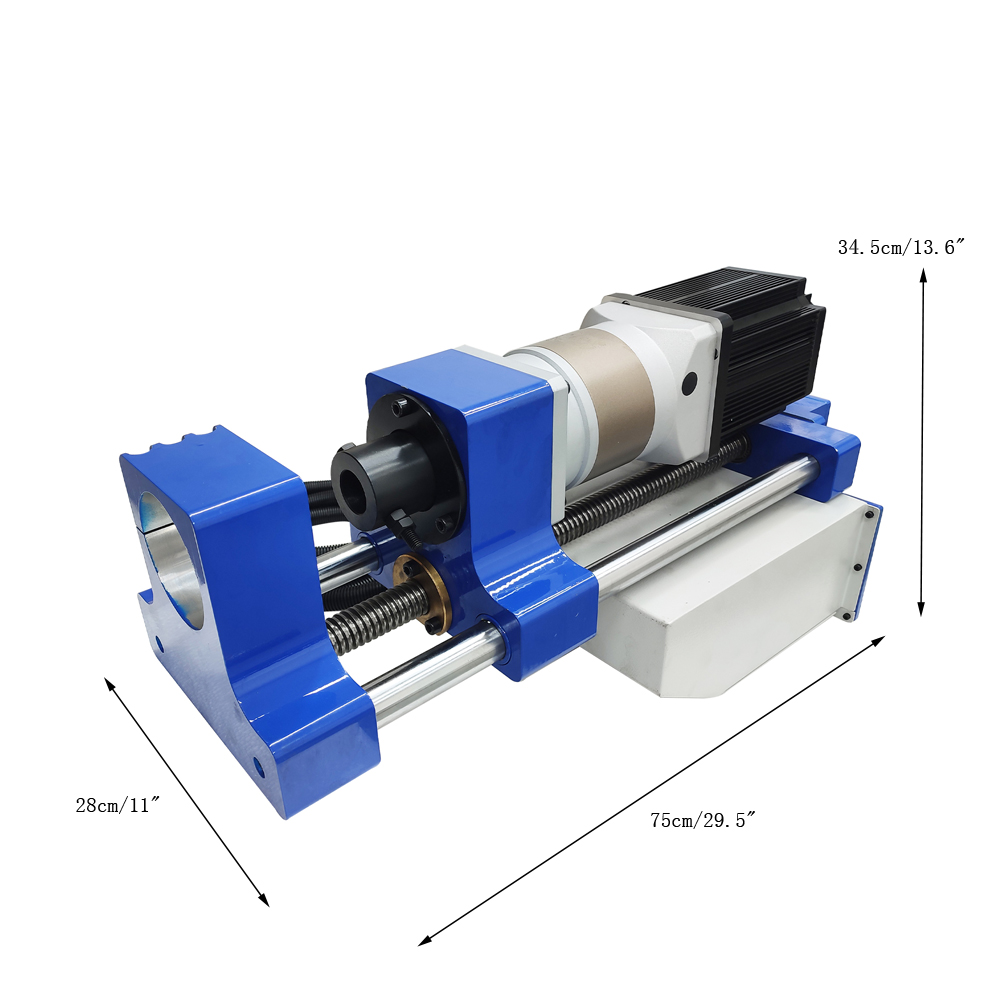

Portable Boring Machine 110V |

|

|

|

|

|

|

|

|

Product

Overview |

The engineering machinery boring machine is

used for repair welding post-processing of shaft pin holes, rotary holes

and hinge holes in various engineering machinery structures, or used for

inserting sleeves after expanding holes. It is also used for repairing

and processing concentric holes of excavators, loaders, presses, cranes

and other machinery.

The 60 type boring machine is installed through the welding and bolted

connection fixing and clamping mode, and is convenient to disassemble

and transport. The 60 type boring machine is suitable for processing

various concentric holes and multiple parallel holes. The boring machine

conducts continuous cutting during work, and has high production

efficiency and high machining accuracy.

|

|

Product

Parameters |

|

Voltage |

110V 50/60HZ |

|

Power of main motor |

2.9KW |

|

Feed power |

120W |

|

Torque of feed motor |

10Nm |

|

Working stroke |

400mm (15.75'') |

|

Rotating speed of main machine |

0-200r/min |

|

Boring diameter |

65-400mm (2.56''-15.75'') |

|

Rotating speed of feed |

Stepless speed regulation |

|

Max. engagement of the cutting edge of single

side |

2mm (0.08'') |

|

Processing roughness |

Ra3.2 |

|

Roundness of processed holes |

≤0.02mm |

|

|

|

|

Attention |

1. Equipment operators should receive the

safety operation training.

2. Equipment operators must wear work clothes, insulated shoes and

protective goggles.

3. Before starting the machine, check whether the on-site power supply

is consistent with the equipment.

4. Before starting the machine, check if the clamping system is locked.

5. When aligning the workpiece, it is only allowed to be pulled manually

in the neutral gear and or to align in the lowest gear. High speed

alignment is not allowed.

6. After the equipment is turned on, please do not allow your hands or

other objects to get close to the equipment to avoid the personal

injury.

7. Wires should be protected from the high temperature, grease, sharp

edges and other places.

8. When there is abnormal sound or a malfunction, the power supply

should be immediately turned off and then the equipment should be

inspected and repaired.

9. The operation of the equipment shall be supervised by a special

person, and it is strictly prohibited for the equipment to operate by

itself.

10. It is strictly prohibited to use the equipment beyond or below the

specified processing range, and our company is not responsible for any

consequences arising therefrom.

11. The equipment cannot exceed the maximum cutting capacity specified.

The direction of the boring bar and the feed direction can only be

switched after the motor has completely stopped. The customers need to

purchase accessories at their own expense for handling all the equipment

damage caused by this misoperation.

12. It is strictly prohibited to change the feed mode after operation.

13. After the work is finished, the oil stains and metal scraps on the

equipment should be cleaned away timely, and anti-rust oil should be

applied timely.

14. According to the maintenance requirements, do a good job in

equipment maintenance and upkeep.

|

|

Product

Features |

|

|

|

|

|

| The

boring machine is mainly used for repair welding post-processing

of shaft pin holes, rotary holes and hinge holes in various

engineering machinery structures, or used for inserting sleeves

after expanding holes. It is also used for repairing and

processing the concentric holes of excavators, loaders, cranes

and other machinery. The boring machine can process parallel

holes in multiple rows, and conducts one-time positioning

processing on the multiple holes to ensure the coaxiality of the

multiple holes. |

|

The 110V motor is

adopted by the spindle and supporting tools of the boring

machine and has the characteristics of low rotating speed and

high torque. The whole machine can achieve stable cutting

processing and has superior performance. Axial movement and

cutting performance are free of vibration. The important

guarantee is provided for high precision, high efficiency, high

stability and high flexibility boring machining. The stability

is better, and the fault rate is lower. |

|

|

|

|

|

| The

feed and spindle conduct stepless speed regulation. The speed

can be adjusted through the independent remote controller and

the speed knob on the main machine, and operation and control

are easy and convenient. |

|

The boring bar is

of an alloy steel structure. After processing and heat

treatment, it has the characteristics of high precision, high

hardness, fatigue resistance, wear resistance, etc. |

|

|

|

|

|

| The

electric control box is designed for the boring machine, the

structure is compact, internal circuits are arranged orderly,

and the circuit safety is effectively ensured. The motor

controller is equipped with a dynamic delay braking device to

avoid vibration during parking. |

|

The tool rests can

be installed and fixed at any position within the effective

travel range. Different tool rests can be selected to adapt to

different workpieces, so that the adaptability is higher. The

tool rests are firm and durable and convenient to replace. |

|

|

Operation

Method |

|

|

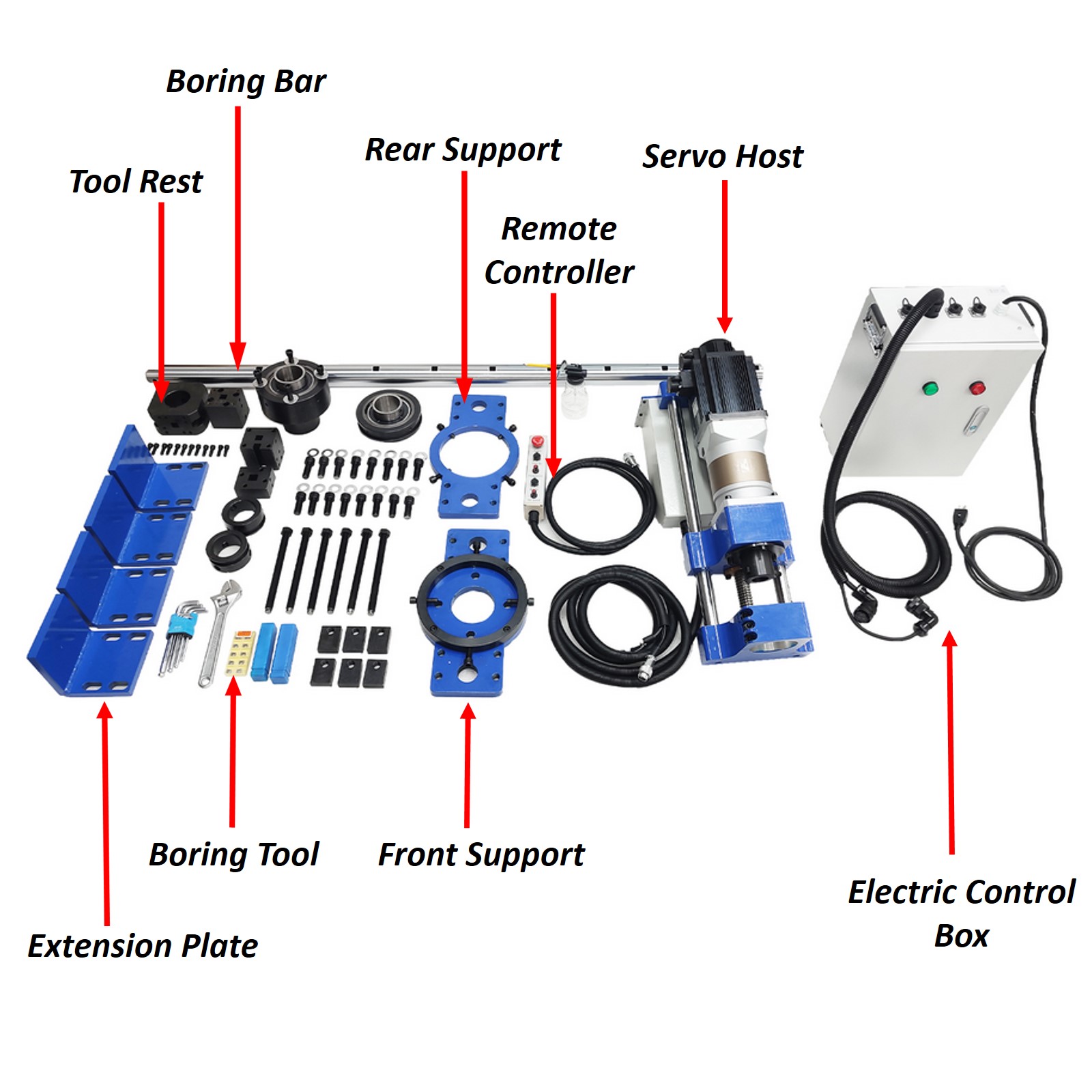

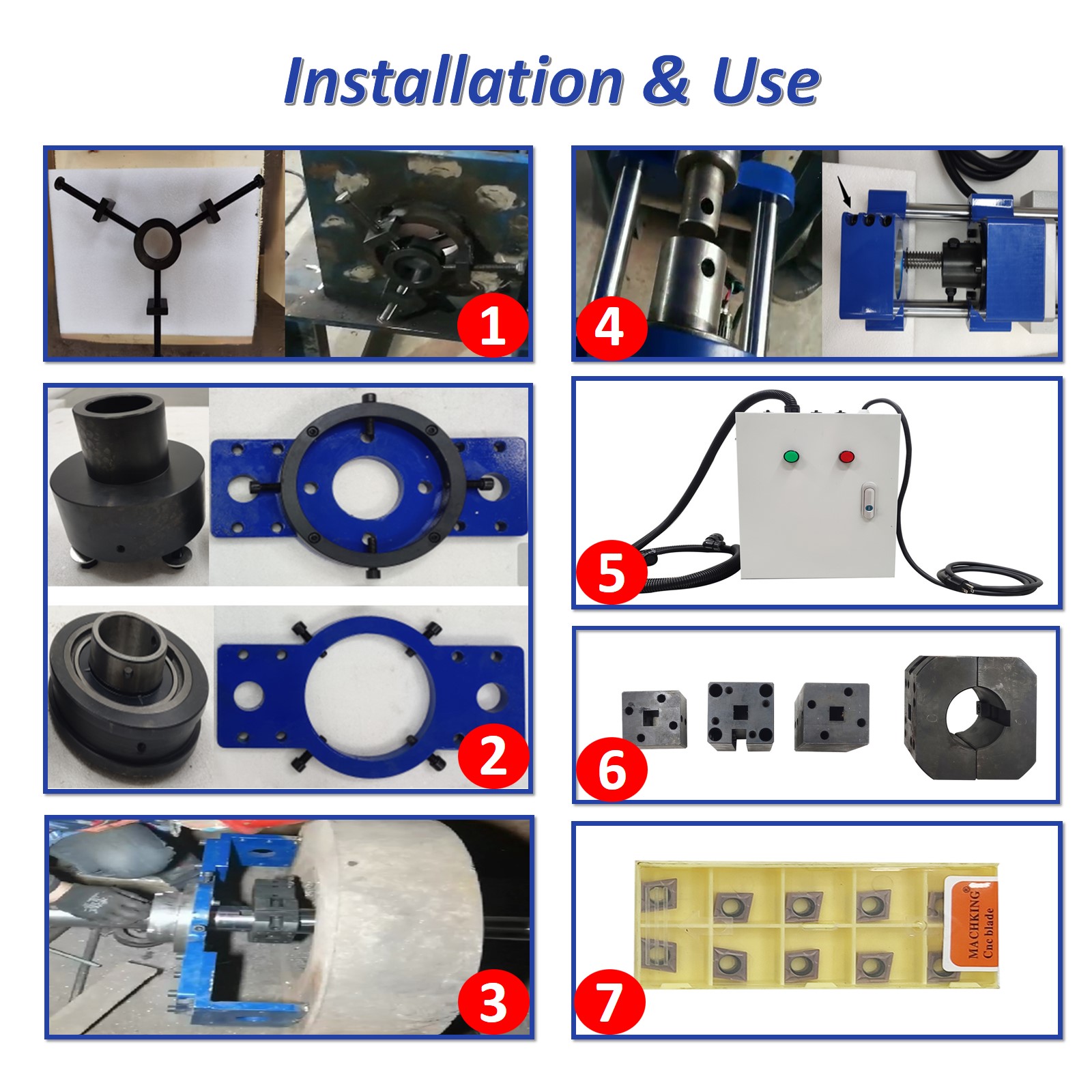

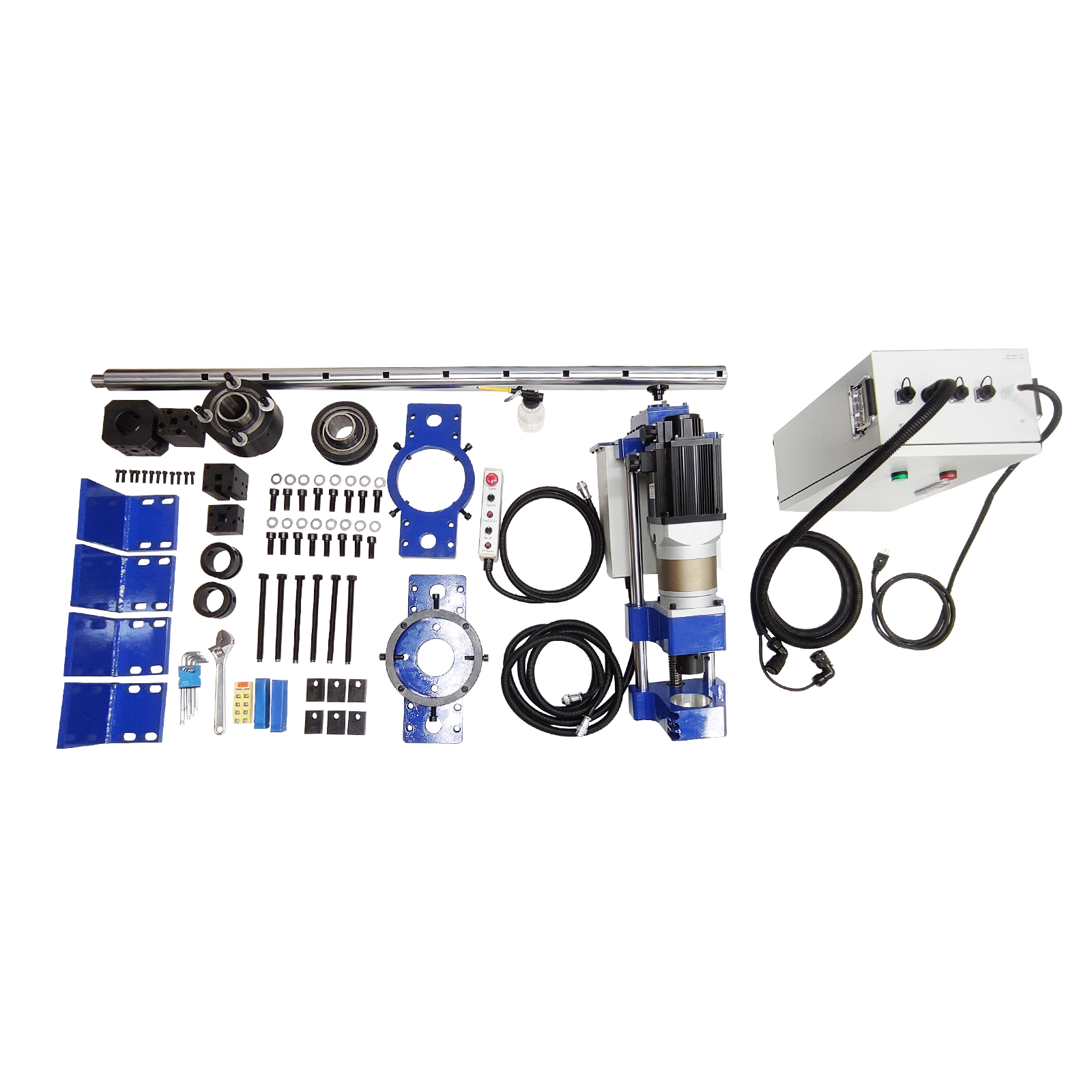

After the product is received, the boring

machine is installed and used according to the following steps. |

1. Installation of Supports

A. Positioning of Boring Rod

Install the supporting bases at the position, where welding is allowed,

of the processed part. Fix the boring bar in the to-be-processed hole

with supporting bolts, and position the boring bar with positioning

sleeves at the two ends to ensure the coaxiality of the two holes.

B. Insert the boring bar into the supporting bases and assemble the two

supporting bases at the appropriate position. During welding, pay

attention to ensuring that each welding bolt is evenly attached to the

workpiece and firmly welded to the workpiece, and also pay attention to

ensuring that the boring bar can rotate flexibly and slide axially. If

the boring bar is not smooth, adjust the nuts on the welding bolts until

it is smooth. |

|

2. After positioning the boring bar in the

center through sleeving installation of the supporting bolts, assemble

the host connection support (front support) and four M18*160 bolts

together, then push the assembled host connection support to the end

face of the machined hole along the boring bar, and adjust the gaps

between the bolts and the end face to be consistent. Then firmly weld

the bolts and the end face. In the same way, assemble the end face

support (rear support), push it to the end face of the machined hole

along the boring bar, adjust the gaps and weld them firmly. |

|

3. After firmly welding the front and rear

supports, remove the positioning sleeves, push and pull the boring bar

to ensure smoothness, and at the same time, install a tool (which can be

a boring tool) that can be used for straightening in the tool

installation hole of the boring bar to conduct straightening operation.

If there is a deviation, the operator can loosen the four M12 hexagon

socket bolts for fixing the bearing pedestals (no need to completely

loosen them, and apply a certain force). There are four M12 jackscrews

around the bearing pedestals, and the boring bar can be fine-tuned to

the ideal position through the jackscrews. The front and rear supports

can be adjusted for several times to achieve the better effect. After

adjustment is finished, be sure to remember to tighten the fastening

screws of the bearing pedestals of the front and rear supports. |

|

4. At this moment, push the host to the host

connection bearing pedestal along the boring bar and connect the host

and the host connection bearing pedestal. Align the bolt on the host

with the fixing hole on the boring bar, insert the bolt into the fixing

hole, lock them, and then tighten the host locking device. It is

suggested that the single-side cutting amount should not exceed 2-3mm. |

|

5. Choose the 110V power supply. Connect the

plug of the electrical control box to the 110V power supply. When a

generator is used, a voltage regulator is required. |

6. Selection of Tool Rests

A. The hole diameter is within the range of 65-90mm, and the cutting

tool is directly fixed in the tool groove.

B. The hole diameter is within the range of 90-400mm, there are two tool

rests that can be selected according to the specific size of the hole

positions. |

7. Installation of Cutting Tool

Fix the CNC cutting tool to the boring bar or tool rest according to the

size of the machined hole.

A. When the tool setting is conducted, please select the neutral gear

and manually rotate the boring bar to adjust the tool and to ensure that

the tool tip is about 0.2mm away from the workpiece.

B. During the initial cutting, choose the single-side cutting depth to

be 0.5-1.0mm for cutting, and carefully observe the cutting condition of

the tool to make accurate judgment for normal cutting. |

|

8. During processing, the amount of feed

should be selected according to the requirements of the cutting depth

(single-side cutting depth: ≤2mm) and the machining accuracy, and the

specific surface conditions of the processed workpiece. The amount of

feed should be controlled to be 0.02-0.16mm per revolution, and the too

fast feed can cause equipment damage. |

|

|

|

Product

Display |

|

|

|

|

Item Number (022842): 1 x

Portable Boring Machine 110V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|